The Mining Process

Development of the CK Gold Project is a multi-phase, multi-year process designed to protect the environment, minimize disturbance to neighbors and allow the safe and economic extraction of the valuable minerals. Before any mining takes place, a number of steps are necessary to determine the viability of the project. Ample planning guided by science helps eliminates uncertainty and creates a sound project plan.

Prefeasibility, economic, and environmental assessments

It is well understood that quantities of gold, copper, silver and zinc exist at the site. The initial phases are all about data collection, data analysis and making plans based upon the findings. The following are examples of the types of questions the assessment phase worked to find answers to. This list is not exhaustive and often answers to one question led to new questions and additional analyisis. Some of the activities that took place were: core drilling, baseline water sampling, wildlife surveys, rock chemistry analysis, land title searches, and economic modeling. The goal was to determine if an economic mining operation is possible. Much of this work was summarized in the updated Prefeasibility Study that was released on February 10, 2025.

Mining and Resource Questions

1. How large of a resource and ore body exists?

2. What is the grade and concentration of the resource?

3. What type of mining method allows the best access to the minable resource?

4. What type of processing method allows for the highest recoveries of the resource?

5. What is the best rate of mining based upon the quantity of ore and capital costs to start the mine? In other words, how long would mining activity last?

6. What are the options for processed ore tailings, overburden and non-ore bearing rock?

7. Is the site easily assessable and what are the best options for access?

Economic Questions

1. How much does it cost to conduct preferred type of mining and processing?

2. What are the forecasts for commodity prices?

3. Are there additional revenue streams?

4. What are the tax rates?

5. What are the local benefits?

6. What are the royalty rates to Wyoming’s education system?

7. How much will it cost and how long would it take to construct the processing plant, purchase equipment, build roads, bring in electricity and the other necessary infrastructure to operate a mine?

8. How much do the environmental bonds cost?

9. What are the estimated reclamation expenses?

10. What are the operational costs such as labor, fuel, water, electricity, and equipment maintenance?

11. What is the economic return and value proposition to shareholders, and does it justify the project?

12. Are there enough investors or financing options to provide the necessary capital?

Environmental Questions

1. Would the project impact nearby water wells, water tables and existing water quality?

2. What is the chemistry of the ore body and surrounding rock?

3. If the rock is exposed to air, water and surface conditions, does the chemistry change?

4. What wildlife species live in the area?

5. Would the mining activities negatively impact wildlife breeding grounds or other critical habitat?

6. What are the various plant species?

7. What does the existing subsurface ground water table look like?

8. Would a mine impact nearby wells’ water quality or production?

9. If the rock chemistry does change due to mining, would there be an impact to the water?

10. Would there be harmful water run off from the site?

Reclamation and Remediation Questions

1. Under existing law, what are the requirements to return the land to an appropriate state?

2. What are the permitting steps?

3. Are there any beneficial post-mine uses of the site? E.g. water storage reservoir or recreational area.

4. Does the site contain all of the elements such as suitable topsoil and geology, to support a successful reclamation plan?

5. What are the requirements necessary for full bond release?

Legal Questions

1. Who owns the various land ownership interests and what has been severed from surface ownership?

2. Are the various owners open to providing the necessary access and if so, what does that look like in principle?

3. What existing infrastructure exists in the area? If so, who owns it and does it need to be relocated or replaced to allow for a mine?

Stakeholder outreach questions

1. What are the general feelings towards a mine in the area?

2. What are the concerns of the area residents?

3. Is the concept supported by local officials?

4. Do regulators have any initial concerns regarding the ability to permit such an operation?

Permitting

The feasibility and assessment work demonstrated that the CK Gold Project is viable and the company filed the necessary permits to construct and operate the mine on September 13, 2022. The regulatory jurisdiction this project falls under the State of Wyoming. The Wyoming Department of Environmental Quality (DEQ) issued the major operating permit in May 2024, the water discharge permit in June 2024, and the Air Quality Permit in November 2024. As the owner of the land, the project will need approval from the State Lands and Investment Board.

In parallel to the mine operating permit, the company also needs an Industrial Siting Permit (ISP) with the DEQ. The ISP process is unique to Wyoming, but ensures the area communities in which large capital construction projects are sited have the resources to accommodate the accompanying workforce. It looks at issues such as traffic, housing and economic impact. The process can also provide impacted communities an advance on the anticipated tax revenue to help mitigate the impacts. The ISP was approved on June 20, 2023.

Additional approvals will be necessary from Laramie County such as right of way, road access and building permits. The site has undergone a historical and cultural assessment as required by Wyoming State Parks and Cultural Resources. The company has worked with Wyoming Game and Fish Department address and mitigate wildlife issues.

The prior feasibility work determined what exact permits are necessary and which regulatory agencies have jurisdiction. U.S. Gold Corp has hired Trihydro Corporation, an environmental and engineering consulting firm headquartered in Laramie, Wyoming, to gather the data and prepare permit applications.

The company will be required by law to post environmental reclamation bonds with DEQ and the Wyoming Office of State Lands to ensure there are adequate resources in place to return the site to its pre-mining use should the company be unable to fulfill its obligation. The amount of the bonds is determined as a part of the permitting process and reassessed annually to ensure adequate coverage. The company has posted bonds for all work conducted thus far and DEQ has released some bonds since US Gold Corp successfully reclaimed and met the conditions to remediate disturbances.

If the all of the necessary permits and approvals are granted, the project would move onto the construction phase.

Currently, the site is accessed via an easement across Ferguson Family ranch land, using the route designated in purple above. The access is off County Road 210 approximately 2 miles west of Happy Jack Road.

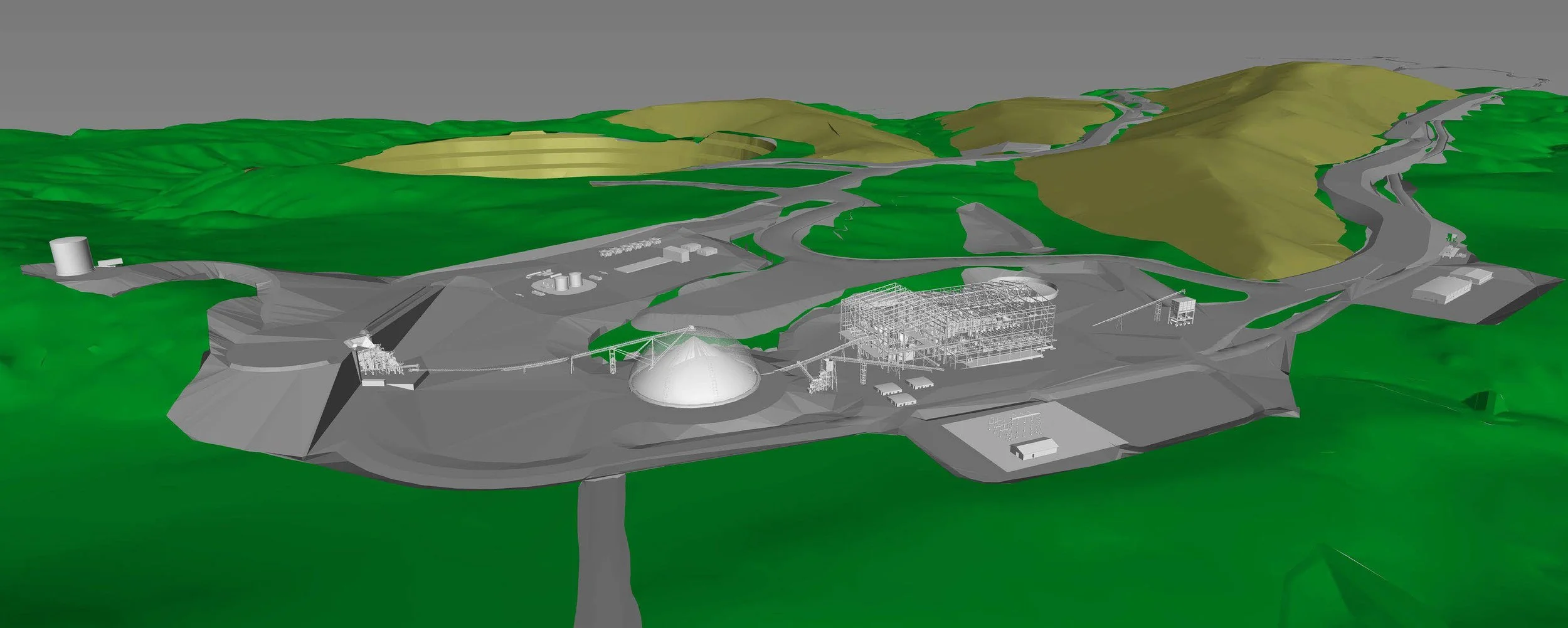

Construction

Construction is estimated to take approximately 18 months. This would include building the access roads to the site, construction of the processing mill, earthworks and site grading, and layout for the tailings storage area.

Rendering of the CK Gold Mine processing plant

Mining

The mining process would utilize equipment and methods similar to the quarry 2.8 miles to the south of the CK Gold Project site. The target ore is hosted in granite and to extract the minerals, the granite must be removed for processing. Non-ore bearing rock will be removed leaving slopes and benches on the mine pit walls in a stable condition to eliminate rockslides, protect workers, and create roadways for equipment to enter and leave the pit. This rock will be set aside to help stabilize the mine tailings prior to reclamation, although some could be sold as aggregate for off-site construction purposes. In an around the clock operation, the mine will produce about 20,000 tons per day of ore bearing material for processing and about 20,000 tons of non-ore bearing granite.

Unlike the quarry operations which remove rock in shallow pits expanding laterally, the CK Gold Project would have a smaller surface disturbance area, but progress much deeper. At the conclusion of mining activities, the surface area of the pit opening would cover about 80 acres, narrowing into a cone shape that will be approximately 800 feet deep. Some initial mining activity may be visible from publicly accessible areas, but would quickly become hidden from view as the pit depth increases and equipment moves below grade.

Similar to the quarry operations, the first step is to drill holes into the granite and insert explosives to loosen the rock. Drilling and blasting is a precisely engineered process, with very specific designs created for the type of rock and the desired effect. The goal of the blast is to simply fracture the rock, keeping it mostly in place. Blasting plans determine the spacing and depth of the holes, how much explosive is used, the blast sequence, and timing. The sequence and timing are very important as a cascade of multiple, smaller blasts is more effective than one large blast. A properly engineered blast sequence can also minimize sound and vibration as successive charges are detonated in a cascade, which can muffle the sound waves of the overall explosion. Blasting would last no more than a few seconds and occur no more than once per day and at a time agreed to by neighboring stakeholders.

Shown here is an example of the type of typical blast sequence that would be seen at the CK Gold Project.

Once the rock has been fractured, front-end loaders move in to the load trucks which would haul the material out of the pit. Ore would be dumped into the crusher to start the metal extraction process and non-ore bearing rock will be set aside. A typical dump truck you see on the street can hold about 15 tons of material, whereas the trucks utilized at the mine would hold 100-150 tons. While large, these trucks are much smaller than those used at coal mines in Wyoming, which can haul as much as 400 tons.

Processing

The ore is dumped into a jaw crusher to reduce the size and is carried to the SAG (semi-autogenous grinding) mill on a conveyor.

Courtesy: Global Crushers

In the SAG mill, water is added and the ore is spun in a cylindrical drum with steel balls to produce a slurry. The slurry is piped to the next stage, where the smaller particles of copper, gold and minerals are captured using a froth flotation process. This video shows the methods and equipment used in processing the raw ore into a concentrate at a copper mine.

Courtesy: Copper Mountain Mining Corporation

This video describes the froth flotation process in greater detail, describing the chemistry and some of the compounds used.

Courtesy: IPMI

The concentrate is the final product that leaves the mine. Approximately five trucks per day of concentrate would be transported to an existing smelter similar to the Kennecott Utah Copper Refinery near Salt Lake City, Utah or other facilities in Asia. There the concentrate would undergo final processing into usable gold, copper, silver and zinc ingots.

Reclamation and post-mining activities

How the site would be reclaimed and ultimately look after mining activity ends is set forth in the reclamation plan as directed within the permit. This plan helps determine the amount of the environmental bonds and shapes how the site is engineered and mined. If the ground needs a particular slope or topography, it is much more economical to conduct those activities contemporaneously during mining.

After processing, the materials remaining after the minerals have been extracted are known as tailings. These tailings, after filter pressing, are similar to a wet sand and would be mixed with a portion of the non-ore bearing granite removed from the pit during mining. Mixing the finer tailings with the larger rock creates a very stable pile that can be contoured into hills and the surrounding topography. Once the tailings have been placed as specified by the mine plan, it would be capped with topsoil and revegetated with native plant species. After the plants are established, the land can then return to its current use, which is livestock grazing. Click here to view examples of mine reclamation from around the world.

After the ore body has been exhausted and mining activities cease, all of the infrastructure would be removed, the land regraded and reclaimed. Some infrastructure, such the road to the site, electrical lines and water wells may be granted to the landowners if they have a beneficial use. For example, local ranchers may want electricity to power wells for livestock drinking water or irrigation, and area homeowners may benefit from cellular phone and communication towers.

U.S. Gold Corp is working with stakeholders on options for the mining pit itself. One option is to refill the pit using the tailings and non-ore bearing rock. Another is utilizing the pit as a water storage reservoir. The nearby Crystal Lake and Granite Springs Reservoirs were created in the early 1900’s by the City of Cheyenne to store water for municipal use. As Cheyenne and the Front Range grows, so does the need for water. The Cheyenne Board of Public Utilities (BOPU) has commissioned several studies showing the need for additional water storage in the coming decades and one of the options is to raise the height of the dams at the Crystal Lake and Granite Springs Reservoirs. This scenario would raise water levels around 14 feet, flooding roads, trails, most of the existing campsites, and other recreational areas within Curt Gowdy State Park. Besides costing ratepayers a significant sum, a dam reconstruction project would have other impacts as well, including increased traffic and the temporary elimination of the reservoirs as they would need to be drained during construction. Any changes to the current plan, which is to fill in the pit and return the land to grazing, would need to be approved by the Wyoming DEQ in a permit modification.

As shown in the graphic below, the mine pit would be carved into solid granite, the same granite formation Crystal Lake and Granite Springs Reservoirs sit upon. Initial investigations support the concept of the pit holding water and being used for water storage with little or no impact to water quality. Along the Front Range, there are many examples of reclaimed mining pits being utilized for this purpose. Using the site for water storage would preserve the existing footprint at Curt Gowdy State Park, maintaining the recreational sites and eliminate a major construction project in the area.

The reservoir idea is still just that, an idea. The first step is to use science to prove the theory that the mine pit would be suitable for water storage. Additional geologic drilling and sampling has not identified any significant fault lines or geologic formations that create leaks into or out of the pit. Chemical analysis of the rocks has shown there would be negligible impacts on water quality. The stakeholders need to agree that such a reservoir fulfills their needs and makes sense for the region. However on the surface, it appears this concept could provide a significant asset at a minimal cost to rate payers and an arid region such as Wyoming could benefit from additional water storage.